Advertisement

-

Published Date

November 11, 2020This ad was originally published on this date and may contain an offer that is no longer valid. To learn more about this business and its most recent offers, click here.

Ad Text

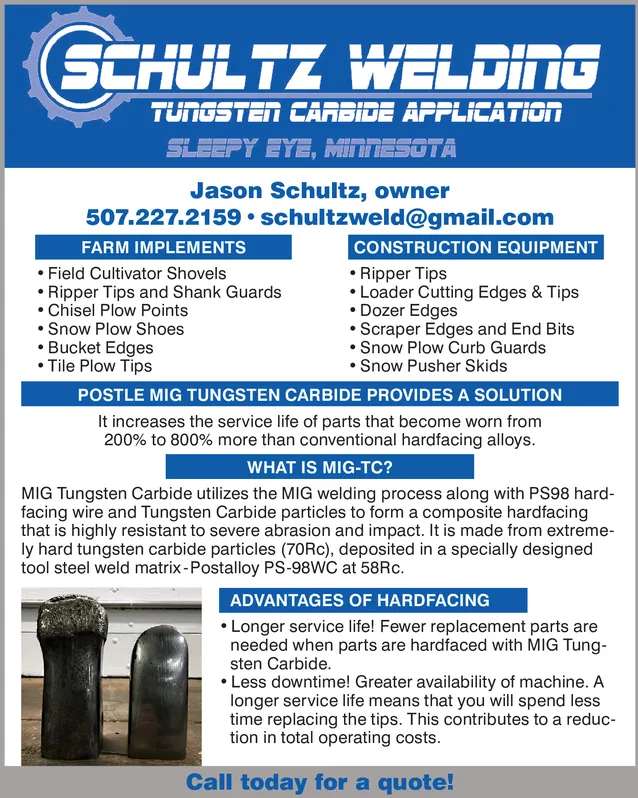

SCHULTZ WELDING TUNGSTET CARBIDE APPLICATION SLEEPY EYE, MMESOTA Jason Schultz, owner 507.227.2159 schultzweld@gmail.com FARM IMPLEMENTS CONSTRUCTION EQUIPMENT Field Cultivator Shovels Ripper Tips and Shank Guards Chisel Plow Points Snow Plow Shoes Bucket Edges Tile Plow Tips Ripper Tips Loader Cutting Edges & Tips Dozer Edges Scraper Edges and End Bits Snow Plow Curb Guards Snow Pusher Skids POSTLE MIG TUNGSTEN CARBIDE PROVIDES A SOLUTION It increases the service life of parts that become worn from 200% to 800% more than conventional hardfacing alloys. WHAT IS MIG-TC? MIG Tungsten Carbide utilizes the MIG welding process along with PS98 hard- facing wire and Tungsten Carbide particles to form a composite hardfacing that is highly resistant to severe abrasion and impact. It is made from extreme- ly hard tungsten carbide particles (70RC), deposited in a specially designed tool steel weld matrix-Postalloy PS-98WC at 58RC. ADVANTAGES OF HARDFACING Longer service life! Fewer replacement parts are needed when parts are hardfaced with MIG Tung- sten Carbide. Less downtime! Greater availability of machine. A longer service life means that you will spend less time replacing the tips. This contributes to a reduc- tion in total operating costs. Call today for a quote! SCHULTZ WELDING TUNGSTET CARBIDE APPLICATION SLEEPY EYE, MMESOTA Jason Schultz, owner 507.227.2159 schultzweld@gmail.com FARM IMPLEMENTS CONSTRUCTION EQUIPMENT Field Cultivator Shovels Ripper Tips and Shank Guards Chisel Plow Points Snow Plow Shoes Bucket Edges Tile Plow Tips Ripper Tips Loader Cutting Edges & Tips Dozer Edges Scraper Edges and End Bits Snow Plow Curb Guards Snow Pusher Skids POSTLE MIG TUNGSTEN CARBIDE PROVIDES A SOLUTION It increases the service life of parts that become worn from 200% to 800% more than conventional hardfacing alloys. WHAT IS MIG-TC? MIG Tungsten Carbide utilizes the MIG welding process along with PS98 hard- facing wire and Tungsten Carbide particles to form a composite hardfacing that is highly resistant to severe abrasion and impact. It is made from extreme- ly hard tungsten carbide particles (70RC), deposited in a specially designed tool steel weld matrix-Postalloy PS-98WC at 58RC. ADVANTAGES OF HARDFACING Longer service life! Fewer replacement parts are needed when parts are hardfaced with MIG Tung- sten Carbide. Less downtime! Greater availability of machine. A longer service life means that you will spend less time replacing the tips. This contributes to a reduc- tion in total operating costs. Call today for a quote!