Advertisement

-

Published Date

September 4, 2019This ad was originally published on this date and may contain an offer that is no longer valid. To learn more about this business and its most recent offers, click here.

Ad Text

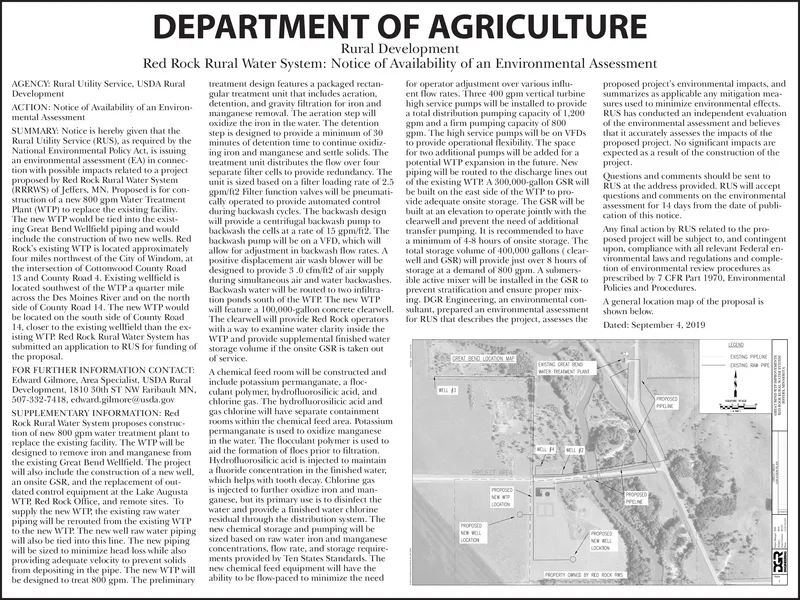

DEPARTMENT OF AGRICULTURE Rural Development Red Rock Rural Water System: Notice of Availability of an Environmental Assessment AGENCY: Rural Utility Service, USDA Rural Development ACTION: Notice of Availability of an Environ mental Assessment proposed project's environmental impacts, and summarizes as applicable any mitigation mea sures used to minimize environmental effects RUS has conducted an independent evaluation of the environmental assessment and believes that it accurately assesses the impacts of the proposed project. No significant impacts are expected as a result of the construction of the project Questions and comments should be sent to RUS at the address provided. RUSS will accept questions and comments on the environmental assessment for 14 days from the date of publi cation of this notice Any final action by RUS related to the pro posed project will be subject to, and contingent upon, compliance with all relevant Federal en- vironmental laws and regulations and comple tion of environmental review procedures as prescribed by 7 CFR Part 1970, Environmental Policies and Procedures eatment design features a packaged rectan- gular treatment unit that includes acration detention, and gravity filtration for iron and manganese removal. The aeration step will oxidize the iron in the water. The detention step is designed to provide a minimum of 30 miutes of detention time to contime oxidiz- ing iron and manganese and settle solids. The for operator adjustment over various influ ent flow rates. Three 400 gpm vertical turbine high service pumps will be installed to provide a total distribution pumping capacity of 1,200 spm and a firm pumping capacity of 800 spm. The high service pumps will be on VFDS to provide operational ilexibility. The space for two additional pumps will be added for a potential WIP expansion in the future. New SUMMARY: Notice is hereby given that the Rural Utility Service (RUS), as required by the National Environmental Policy Act, is issuing an environmental assessment (EA) in connec tion with possible impacts related to a project proposed by Red Rock Rural Water System (RRRWS) of Jeffers, MN. Proposed is for con- struction of a new 800 gpm Water Treatment Plant (WIP) to replace the existing facility The new WIP would be tied into the exist ing Great Bend Wellfiekd piping and would include the construction of two new wells. Red Rock's existing wTP is located approximately four miles nortlwest of the City of Windom, at the intersection of Cottonwood County Road 13 and County Road 4. Existing wellfield is located southwest of the WTP a quarter mile across the Des Moines River and on the north side of County Road 14. The new WTP would be located on the south side of County Road 14, closer to the existing wellfield than the ex isting WTP Red Rock Rural Water System has submitted an application to RUS for funding of the proposal FOR FURTHER INFORMATION CONTACT Ecward Gilmore, Area Specialist, USDA Rural Development, 1810 30th ST NW Faribault MN, 507-332-7418, edward.gilmore@usda.gov treatment unit distributes the flow over four separate filter cells to proide redunddancy. The piping will be routed to the discharge lines out unit is sized based on a filter loading rate of 2.5 of the existing WITE A 300,000-gallon GSR will spm/i2 Filter function valves will be pneumati- cally operated to provide automated control during backwash cycles. The backwash design will provide a centrifugal backwash pump to backwash the cells at a rate of 15 gpm/t2. The backwash pump will be on a VFD, which will allow for adjustment in backwash flow rates. A positive displacement air wash blwer will be designed to provide 3.0 cfm/ft2 of air supply during simultaneous air and water backwashes Backwash water will be routed to two infiltra ion ponds south of the WTP The new WTP will feature a 100,000-gallon concrete cleawel. The clearwell will provide Red Rock operators with a way to examine water clarity inside the wTP and provide supplemental finished water storage volume if the onsite GSR is taken oi of service A chemical feed room will be constructed and include potassium permanganate, a floc culant polymer, hydrofluorosilicic acid, and chlorine gas. The hydrofluorosilicic acid and gas chlorine will have separate containment oms within the chemical feed area. Potassium permanganate is used to oxidize manganese in the water. The flocculant polymer is used to aid the formation of floes prior to filtration Hydroluorosiliic acid is injected to maintain a fuoride concentration in the finished water, which helps with tooth decay. Chlorine gas is injected to further oxidize iron and man ganese, but its primary use is to disinfect the water and provide a finished water chlorine residual through the distribution system. The new chemical storage and pumping will be sized based on raw water iron and manganese concentrations, flow rate, and storage require- ments provided by Ten States Standards. The new chemical feed equipment will have the ability to be flow-paced to minimize the need be built on the east side of the WIP to pro vide adequate onsite storage. The GSR will be built at an elevation to operate jointly with the clearwell and prevent the need of additional transfer pumping. It is recommended to have a minimum of 4-8 hours of onsite storage. The total storage volume of 400,000 gallons (clear- well and GSR) will provide just over 8 hours of storage at a demand of 800 gpm. A submers ible active mixer will be installed in the GSR to prevent stratification and ensure proper mix- ing. DGR Engineering, an environmental con- suant, prepared an environmental assessment for RUS that describes the project, assesses the A general location map of the proposal is shown below Dated: September 4, 2019 CREAT BEND LOGATION MA SNG ORCAT rER HEAVEN PPAN MELL43 o PPILN SUPPLEMENTARY INFORMATION: Red Rock Rural Water System proposes constric tion of new 800 gpm water treatment plant to replace the existing facility. The WIP will be designed to remove iron and manganese from the existing Great Bend Wellfield. The project will also include the construction ofa new well an onsite CSR, and the replacement of out dated control equipment at the Lake Augusta WT Red Roxk Office, and remote sites. To supply the new WT the existing raw water piping will be rerouted from the existing WIP to the new WIP The new well raw water piping will also be tied into this line. The new piping will be sized to minimize head loss while also providing adequate velocity to prevent solids from depositing in the pipe. The new WIP will be designed to treat 800 gpm. The preliminary PROPOSD 0CATON HOPOSD ROPOS NOW OCATION OCKON DEPARTMENT OF AGRICULTURE Rural Development Red Rock Rural Water System: Notice of Availability of an Environmental Assessment AGENCY: Rural Utility Service, USDA Rural Development ACTION: Notice of Availability of an Environ mental Assessment proposed project's environmental impacts, and summarizes as applicable any mitigation mea sures used to minimize environmental effects RUS has conducted an independent evaluation of the environmental assessment and believes that it accurately assesses the impacts of the proposed project. No significant impacts are expected as a result of the construction of the project Questions and comments should be sent to RUS at the address provided. RUSS will accept questions and comments on the environmental assessment for 14 days from the date of publi cation of this notice Any final action by RUS related to the pro posed project will be subject to, and contingent upon, compliance with all relevant Federal en- vironmental laws and regulations and comple tion of environmental review procedures as prescribed by 7 CFR Part 1970, Environmental Policies and Procedures eatment design features a packaged rectan- gular treatment unit that includes acration detention, and gravity filtration for iron and manganese removal. The aeration step will oxidize the iron in the water. The detention step is designed to provide a minimum of 30 miutes of detention time to contime oxidiz- ing iron and manganese and settle solids. The for operator adjustment over various influ ent flow rates. Three 400 gpm vertical turbine high service pumps will be installed to provide a total distribution pumping capacity of 1,200 spm and a firm pumping capacity of 800 spm. The high service pumps will be on VFDS to provide operational ilexibility. The space for two additional pumps will be added for a potential WIP expansion in the future. New SUMMARY: Notice is hereby given that the Rural Utility Service (RUS), as required by the National Environmental Policy Act, is issuing an environmental assessment (EA) in connec tion with possible impacts related to a project proposed by Red Rock Rural Water System (RRRWS) of Jeffers, MN. Proposed is for con- struction of a new 800 gpm Water Treatment Plant (WIP) to replace the existing facility The new WIP would be tied into the exist ing Great Bend Wellfiekd piping and would include the construction of two new wells. Red Rock's existing wTP is located approximately four miles nortlwest of the City of Windom, at the intersection of Cottonwood County Road 13 and County Road 4. Existing wellfield is located southwest of the WTP a quarter mile across the Des Moines River and on the north side of County Road 14. The new WTP would be located on the south side of County Road 14, closer to the existing wellfield than the ex isting WTP Red Rock Rural Water System has submitted an application to RUS for funding of the proposal FOR FURTHER INFORMATION CONTACT Ecward Gilmore, Area Specialist, USDA Rural Development, 1810 30th ST NW Faribault MN, 507-332-7418, edward.gilmore@usda.gov treatment unit distributes the flow over four separate filter cells to proide redunddancy. The piping will be routed to the discharge lines out unit is sized based on a filter loading rate of 2.5 of the existing WITE A 300,000-gallon GSR will spm/i2 Filter function valves will be pneumati- cally operated to provide automated control during backwash cycles. The backwash design will provide a centrifugal backwash pump to backwash the cells at a rate of 15 gpm/t2. The backwash pump will be on a VFD, which will allow for adjustment in backwash flow rates. A positive displacement air wash blwer will be designed to provide 3.0 cfm/ft2 of air supply during simultaneous air and water backwashes Backwash water will be routed to two infiltra ion ponds south of the WTP The new WTP will feature a 100,000-gallon concrete cleawel. The clearwell will provide Red Rock operators with a way to examine water clarity inside the wTP and provide supplemental finished water storage volume if the onsite GSR is taken oi of service A chemical feed room will be constructed and include potassium permanganate, a floc culant polymer, hydrofluorosilicic acid, and chlorine gas. The hydrofluorosilicic acid and gas chlorine will have separate containment oms within the chemical feed area. Potassium permanganate is used to oxidize manganese in the water. The flocculant polymer is used to aid the formation of floes prior to filtration Hydroluorosiliic acid is injected to maintain a fuoride concentration in the finished water, which helps with tooth decay. Chlorine gas is injected to further oxidize iron and man ganese, but its primary use is to disinfect the water and provide a finished water chlorine residual through the distribution system. The new chemical storage and pumping will be sized based on raw water iron and manganese concentrations, flow rate, and storage require- ments provided by Ten States Standards. The new chemical feed equipment will have the ability to be flow-paced to minimize the need be built on the east side of the WIP to pro vide adequate onsite storage. The GSR will be built at an elevation to operate jointly with the clearwell and prevent the need of additional transfer pumping. It is recommended to have a minimum of 4-8 hours of onsite storage. The total storage volume of 400,000 gallons (clear- well and GSR) will provide just over 8 hours of storage at a demand of 800 gpm. A submers ible active mixer will be installed in the GSR to prevent stratification and ensure proper mix- ing. DGR Engineering, an environmental con- suant, prepared an environmental assessment for RUS that describes the project, assesses the A general location map of the proposal is shown below Dated: September 4, 2019 CREAT BEND LOGATION MA SNG ORCAT rER HEAVEN PPAN MELL43 o PPILN SUPPLEMENTARY INFORMATION: Red Rock Rural Water System proposes constric tion of new 800 gpm water treatment plant to replace the existing facility. The WIP will be designed to remove iron and manganese from the existing Great Bend Wellfield. The project will also include the construction ofa new well an onsite CSR, and the replacement of out dated control equipment at the Lake Augusta WT Red Roxk Office, and remote sites. To supply the new WT the existing raw water piping will be rerouted from the existing WIP to the new WIP The new well raw water piping will also be tied into this line. The new piping will be sized to minimize head loss while also providing adequate velocity to prevent solids from depositing in the pipe. The new WIP will be designed to treat 800 gpm. The preliminary PROPOSD 0CATON HOPOSD ROPOS NOW OCATION OCKON